Sree Fabricators

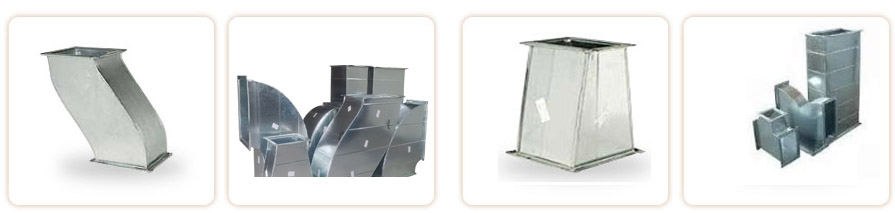

Our Products & Services

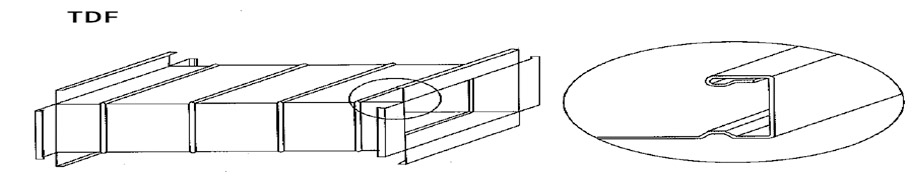

Rectangular Ducting/ Square Ducting is produced using an automatic machinenary that is able to create Transverse Duct Flange (TDF). By using TDF, leaks can be reduced and installations will be easier and more economical. This is because each process of connecting rectangular/square ducts uses TDF Corner, not just any other rectangular metal connectors.

Benefits:

- More ECONOMICAL: No Angle Flange required to connect ducting joints.

- The size is much more PRECISE than manual measurement.

- The RISK OF LEAKS is reduced greatly compared to products that manually created.

- The PRODUCTION and INSTALLATION process is much FASTER and more efficient than normal rectangular ducting production

Work System

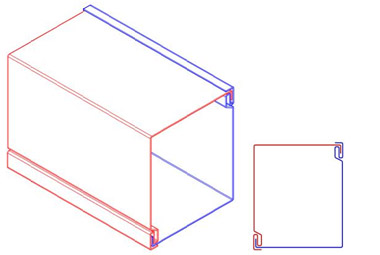

1. L - Shape

Joints in L form or two parts of longitudinal Pittsburgh seams.

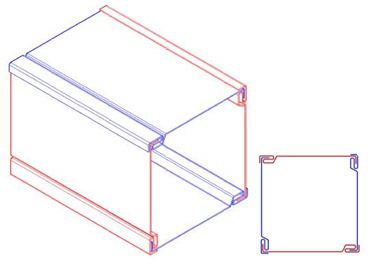

2. Four Piece

Joints of four-piece or four parts of longitudinal Pittsburgh seams.

TDF is a flanging system that consists of forming a flange profile on the duct ends, thus made out of a sheet from which the duct is fabricated. TDF is a 4 bolt duct connection system that eliminates time wastage. Rather than using separate connectors to assemble your system, TDF flanges are rollformed onto duct during the manufacturing process. This connection minimizes leakage and installation costs. These TDF flange eliminates the additional internal sealing around the edges of duct & thereby saves the labour & material.

Features :

- Highly accurate flange profiles and components ensure ease of fitting and high quality assembly.

- A Recessed groove on flange and radial groove on corner pieces for proper gasket seating

- Snap fit corner pieces to allow easy fitting at sites

- Flexibility to use suit-to-site pieces

Slip & Drive Cleats System

Slip and Drive Cleats system is generally used for low-end, less-critical applications. Traditionally, only the Drive cleats ("C") which are positioning cleats were used for all four sides. This was giving a poor joint. The Slip cleats ("S" / "Standing S") on the alternate opposite sides provide the moderate rigidity to the joint.

While installing, Drive cleats are always fitted on the shorter sides and Slip cleats on the longer sides.

The benefits of pre fabricated duct over site fabricated are:

- Low lead time leading to faster project completion

- Low leakage leading to lower energy loss.

- Ducts are made from G.I.coils instead of sheets.

Thus the duct is aligned properly after installation while the ducts made out of sheets will be out of alignment as the reference point is the corner of the sheet which itself is not at right angle. The straight ducts are made on Autofolder, which aligns, makes stiffening braces, notches, and bends, and cuts the duct to the size all in a sequence as data is fed into the machine directly from the drawing.

With G.I. Coils we have consistency in the quality of the material, while in sheets we do not know if the entire lot is of the same quality as there is a lot of seconds material available in market which cannot be differentiated by naked eye.

The elbows, offsets, profiles, tapers etc are made on a machine called plasma profile cutter.

The male parts of the profile are made on a machine called flanger and not by hand thus loosing consistency.

The LAPAT (curved side) of the elbow is made on the rolling machine and not by hand again. The Pittsburgh lock is made on the Roll-former.

As the machines are all CNC automated we provide a detailed computer generated packing list and area summary with each duct numbered.

We can offer pre fabricated ductwork to meet any standards, IS, SMACNA, or even a standard created by customer/ consultant.

- Fast to assemble at site, this leads to fast completion of project.

- Less leakages as compared to site fabricated ducts, which leads to energy saving in terms of electricity.

- Factory fabricated ducts are fully galvanized system, which leads to longer life as compared to site fabricated ducts.

Special Notes :

Cleats

- G. I. Metal Cleat 100 mm in length can be snap-fitted or slid over the mating flanges.

Gasket

- Self adhesive, microcellular, cross-linked, Polyethylene foam type. (Alternatives : PVC or Neoprene)

Bolts, Nuts and Washer

- Electro-galvanised, square-necked carriage bolts, with flanged nuts or nuts and washers.

- Each joint requires 4 sets.Two round holes are provided for alignment while connecting two duct sections.

Corner Design:

- Raised contour in the corner piece to match the recessed groove of the flange, for achieving low leakage.

- Square hole to match the square neck carriage bolt which can be tightened using one hand only ( useful at heights)

- Holes to facilitate alignment of the duct assembly.

- Strong, stiff corners to avoid bending during transportation and storage.

Design Criteria

- Indigenous components only.

- Ultra-low air leakage in the system, to save on energy costs.

- A very high strength-to-weight ratio, to minimise the raw material costs.

- High productivity at job sites through ease assembly and installation.

• Slip-on Feature of the assembled flange.

• Easy fastening of flanges with duct sides (by punch-lock fastener, pop-rivets, self-tapping screws or spot-welding.)

• Requires only four corners bolts to be tightened.

Terminal Box

- Made from 120 GSM Gl material

- Available in factory assembled or knocked down condition

- Stopping bead for proper sitting of flexible duct on round collar

- Available with hanging clips

- Higher GSM (Optional)

Square To Round Piece (VAV Transition pieces)

- Made from 120 GSM Gl material

- factory assembled

- Stopping bead for proper sitting of flexibla duct

- Various connector options available for square/rectangular portion (i.e. TDF, MS angle or C&S flange)

Spigot Damper(butter fly dampers)

- Made from 120 GSM Gl material, Fully galvanized construction & meet SMACNA standards

- Stopping bead for proper sitting of flexible duct

- Sturdy quadrant for easy movement of damper blade

- Higher GSM (Optional)

Fire rated and smoke outlet ductwork

An industry guide to design and installation

Duct/Ductwork - Fire Resisting Smoke Outlet

A fire resisting smoke outlet duct, for the extraction of products of combustion, designed and tested to satisfy the criteria defined in BS 476: Part 24. (ISO 6944). A smoke outlet duct must retain at least 75% of its cross-sectional area throughout the test.

Duct/Ductwork - Fire Resisting Kitchen Extract

A duct or ductwork that is installed entirely independent of any other duct or ductwork within the building and which serves as an extract for non-domestic kitchens (see clause 9.5 of BS 5588: Part 9), designed and tested to satisfy the criteria defined in BS 476: Part 24. (ISO6944).